Over the years I have taken many trips to the C&TS RR at both Chama and Antonito, to take measurements and photographs of the k36, with the intention of producing the most accurate drawings available of the locomotive. That's a tall order. I even visited the K36 displayed at the Royal Gorge in Colorado several times, engine number 486, until it was sold and moved to Silverton.

There is a host of details that are never usually seen and to get the needed information I've had to go when an engine was torn down for repair and refit.

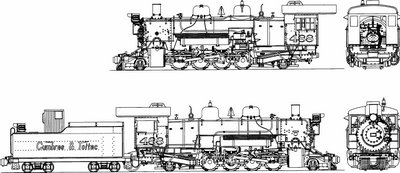

Below are some K36 elevations... so far, and far from finished.

Supposedly easy to get details of the firebox (below) have sometimes taken long trips and days of effort.

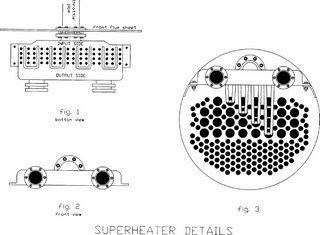

Details of the superheater manifold and piping (below) can only be collected when a K36 is in the shop, opened up, and cold.

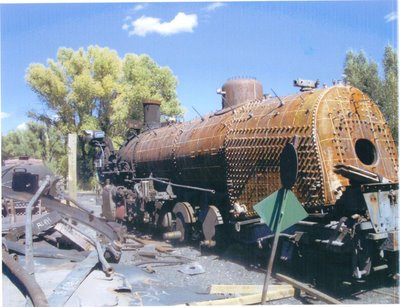

They say the "devil is in the details"... no kidding! There are things on these locomotives you couldn't possibly imagine. But, when you find a K36 in the shape seen below, it becomes a lot easier to get the measurements to the decimal point I need, .0312, or 1/32".

When your bumping your forehead up against the superheater manifold while deep inside the smokebox as shown below, it allows for some pretty accurate measurements.

See those horizontal and vertical lines on the boiler and firebox? I suspect some modeling company had sent one of their people to take measurements for a possible K36 model. I recall that when engine 463, the "Gene Autry" engine was acquired, I spent a bit of time talking with a guy from one of the modeling companies who spent a total of thirty days in Chama getting measurements. The guy was so secretive about his work you'd of thought the CIA had sent him. Yes, it does take a lot of time and money to do this, so the results can be valuable to somebody.

The below drawing of a typical K36 smokebox is about as far as I'm going to go with accuracy and detail, particularly if I ever hope to finish. Keep in mind all this has also been drawn and rendered as a 3d model, so everything had to fit. The hinges were a nightmare to do in 3d.

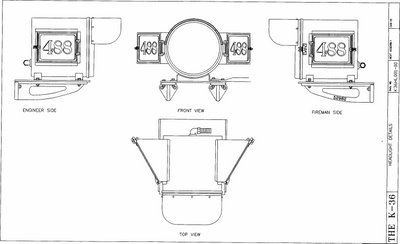

Even the headlight (below) required measuring and re-measuring, checking and re-checking.

I've learned one thing with all this photographing and measuring, there's no two K36's that measure the same just about anywhere you chose to look, so I've been drawing a "typical" K36, because I just won't live long enough to do each one separately, and lordy... who would want to?

1 comment:

Dear Sir,

I do appreciate your effort, but you might live long enough for yourself and others to go through the drawings till the end. If I was still in the states where I left colorado in 1998 I would have joined efforts with you. Since you are carrying out the field measurements, I would gladly volunteering join efforts with you to transfer them into a cad drawing. I do not mind carrying out relatively good measurements from photos and images, but basic main measurements are needed.

I am an egyptian civil engineer, but the reason for myself to get into engineering was railways and locomotives. My extreme long dream, somehow to able to design a complex steam locomotive or know how to design one and somehow when the world is ready to redesign one freshly with our current tools ( similar to the P1 and P2 in the UK ).

I thank you for your efforts and good luck.

Eehab Khalil

Post a Comment